Tien-I Chrome Socket VS. Impact Socket

What is a Regular Socket?

Regular socket also called hand sockets, which are made of CR-V heat

treated to a hardness range commensurate with their size and configuration. Hand sockets are heat treated to a comparatively higher hardness for high strength and more wear resistance than impact sockets.

Hand sockets have a thin wall which allows for clearance in general applications where hand torquing is used.Tien-I Hand sockets are usually chrome

plated.

What is a a Impact Socket?

Tien-I impact socket made out of CR-MO is heat treated to a low hardness range which has been optimized for impact use. This means that under heavy, continuous use, an impact socket will withstand the impact blows and will wear rather than break.

Tien-I impact socket got thick walls and finished in a black phosphate. Impact sockets have a cross hole in the handle end for use with a retaining pin and ring or locking pin anvil to allow the socket to be securely attached to the square drive of an impact gun.

Difference between impact socket and regular socket

First, don't use a chrome socket on the impact gun, since it will cause uncertain damage to the tool itself. It will also delay work efficiency and even cause safety issues. Other than colors, Tien-I Impact socket got very difference with Chrome socket in material and manufacturing process. The design applications for both sockets are also different.

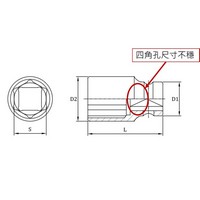

Shape

Wall Thickness:

- Manual Sockets: Generally have thinner walls, which makes them lighter and easier to use in tight spaces. However, this also makes them less durable under high-torque conditions.

- Impact Sockets: Have thicker walls to withstand the high torque and impact forces. The increased wall thickness adds to their durability but also makes them heavier and sometimes bulkier.

Material

- Regular Sockets: These are typically made from chrome vanadium steel, which offers a good balance of strength and flexibility. The finish is usually polished chrome, which provides corrosion resistance and an attractive appearance. Manual sockets are designed to be used with hand tools, such as ratchets and torque wrenches.

- Impact Sockets: These are made from chrome molybdenum steel or other high-strength materials. They have a black oxide or phosphate finish to reduce chipping and corrosion. Impact sockets are designed to withstand the high torque and vibration produced by impact wrenches and pneumatic tools.

Impact VS. Regular Sockets

Regular sockets are more likely to crack and cause hazards due to their higher hardness when used with impact guns. In contrast, impact sockets have higher toughness, making

them more suitable for the high-torque environment of pneumatic guns. That's why Tien-I OEM/ODM sockets are the best selection for the professional market.

Tien-I Sockets VS. Series Article:

- cr-v cr-mo impact sockets: CR-V CR-MO impact sockets, which one is better?

- Six-Point Sockets vs. Twelve-Point Sockets: Hex Points Socket and Twelve Points Socket

Tien-I Related Product Recommendation

If you want to know more about how Tien-I make the quality socket and impact socket for pro brands around the world, please check below link:

"from concept to quality tools"

Tien-i is Taiwan’s leading manufacturer of professional hand tools. We welcome requests from various field industries and brands who are interested in quality hand tools. If you have any questions, please contact our helpful team of experts.

.jpg)

What kind of factory is Tien-i?

Is the bit head magnetic?

What is the popular size of impact sockets?

What kind of tool kit do you want? And what’s the sales territory? Different countries have different popular sizes. Welcome to send us an email for further discussion. .

linkWhat is the popular size of chrome sockets?

What kind of tool kit do you want? And what’s the sales territory? Different countries have different popular sizes. Welcome to send us an email for further discussion.

linkWhat is the difference between impact socket and chrome socket? Why is CR-V material not suitable at producing impact sockets?

Tien-i's hand sockets are made of Cr-V steel (CR-V).

Compared with the raw material "CR-V" for hand sockets, the raw material for pneumatic sockets, CR-MO, has stronger toughness, i.e. stronger shock resistance. Suitable for use with air and electric guns. CR-V steel (CR-V) has higher hardness, but in the need for shock-resistant use environment will lead to reduced service life.

to know more about hand socket and impact socketHow to get the Tien-I catalog?

How to inquiry the products which does not in the Tien-I’s catalog?

Please contact our sales team. It’s welcome to provide the relative drawing or sample and the product sales information.

Please contact our sales team. It’s welcome to provide the relative drawing or sample and the product sales information.How to get the sample? What is the sample cost?

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

-240px.jpg)

-240px.jpg)

(2).jpg)

-240px.jpg)

-240px.jpg)

.jpg)

.png)

.jpg)

.jpg)

![Story in Tokyo DIY Show [Site Photos]](/img/News/IMG_9495 500x500.JPG)

![Brutal Test: Socket Salt Spray Testing 48-Hours [Video]](/img/News/Salt Spray Test(1).jpg)

![A look inside the Great Tool Catalog [PDF Free Download]](/img/News/Why_catalog_important_cr.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

.jpg)