What Makes a Tool Handy?

What exactly makes a tool handy?

How do you make a well-designed, user-friendly, quality hand tool? Before going any deeper, let’s first define what we mean by handy.

People who regularly use hand tools develop a sense of whether or not a classic tool is easy to work with. You know a good ratchet handle by the way you can smoothly change direction

without looking at it, and how it connects perfectly with the socket. Its grip comfortably fits the palm, especially when you rotate it.

I recently discussed this topic with my wife. She was curious as to what exactly makes a hand tool handy. To her, every ratchet handle looks similar. The best explanation I could offer at the time was: You try it, and you just know. As you might imagine, this

wasn’t particularly helpful for her. I began to wonder how one might describe the defining qualities of a handy tool in layman’s terms. When a tool is handy, you can simply feel it. It has a utilitarian and ergonomic design. It’s precise and sensitive and

feels easy and pleasurable to use. Perhaps that’s what I should have told her.

Later, I read the classic philosophy book, Zen and the Art of Motorcycle Maintenance, which contains many insightful descriptions of the sense I was attempting to describe. I’ll take the liberty of quoting these passages below.

"......There's what's called ``mechanic's feel,'' which is very obvious to those who know what it is, but hard to describe to those who don't; and when you see someone

working on a machine who doesn't have it, you tend to suffer with the machine.

.....The mechanic's feel comes from a deep inner kinesthetic feeling for the elasticity of materials. Some materials, like ceramics, have very little, so that when you

thread a porcelain fitting you're very careful not to apply great pressures. Other materials, like steel, have tremendous elasticity, more than rubber, but in a range in which, unless you're working with large mechanical forces, the elasticity isn't apparent.

......With nuts and bolts you're in the range of large mechanical forces and you should understand that within these ranges metals are elastic. When you take up a nut there's

a point called ``finger-tight'' where there's contact but no takeup of elasticity. Then there's ``snug,'' in which the easy surface elasticity is taken up. Then there's a range called ``tight,'' in which all the elasticity is taken up. The force required to

reach these three points is different for each size of nut and bolt, and different for lubricated bolts and for locknuts.

......The forces are different for steel and cast iron and brass and aluminum and plastics and ceramics. But a person with mechanic's feel knows when something's tight

and stops. A person without it goes right on past and strips the threads or breaks the assembly.

.....A "mechanic's feel'' implies not only an understanding for the elasticity of metal but for its softness."

.....The insides of a motorcycle contain surfaces that are precise in some cases to as little as one ten-thousandth of an inch. If you drop them or get dirt on them or

scratch them or bang them with a hammer they'll lose that precision. It's important to understand that the metal behind the surfaces can normally take great shock and stress but that the surfaces themselves cannot."

.....When handling precision parts that are stuck or difficult to manipulate, a person with mechanic's feel will avoid damaging the surfaces and work with his tools on the nonprecision surfaces of the same part whenever possible. If he must work on the surfaces themselves, he'll always use softer surfaces to work them with. Brass hammers, plastic hammers, wood hammers, rubber hammers and lead hammers are all available for this work. Use them. Vise jaws can be fitted with plastic and copper and lead faces. Use these too. Handle precision parts gently. You'll never be sorry. If you have a tendency to bang things around, take more time and try to develop a little more respect for the accomplishment that a precision part represents."

(Robert M. Pirsig.Zen and the Art of Motorcycle Maintenance. (New York: William Morrow, 1974.))

You can feel that the author truly loves motorcycles and enjoys DIY. He recommends buying quality hand tools. If your budget won’t stretch to cover brand-new quality hand tools, buying

used tools of high quality would still be preferable to buying new ones of low quality. Used, high-end tools are more durable than new, low-end tools.

Despite a motorcycle’s tough-looking exterior, the engine is filled with precise and sensitive parts and shouldn’t be handled by any person who lacks the "mechanic's feel."

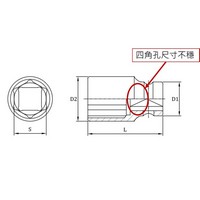

High-quality hand tools allow a mechanic to sense subtle differences in torque and tension of bolts. That’s why manufacturing quality tools requires strict monitoring of tolerance control by precision CNC machines, a consistent raw material source and stable

heat treatment. Any variation in the above factors will cause irregularities in the durability, precision and quality of the end product.

Tien-I has a deep understanding of how to make truly handy tools that are esteemed by professionals and DIY enthusiasts alike. If you are interested in finding a reliable source of quality hand tools, feel free to

contact our friendly and knowledgeable team.

Being a professional hand-tool manufacturer, Tien-I produces complete ISO and ANSI specifications for socket, impact socket, and tube spanner tools. Whether in metric or inch size, Tien-I can meet or even exceed the required specifications. Since 2004, Tien-I Company has continued to design and innovate the latest ergonomics hand tools in Taiwan, and ergonomics has become a part of Tien-I's design and production DNA. If you have any inquiries, just contact Tien-I.

If you like to know more about tool story, simply click below button:

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

-240px.jpg)

-240px.jpg)

(2).jpg)

.jpg)

.jpg)

![Story in Tokyo DIY Show [Site Photos]](/img/News/IMG_9495 500x500.JPG)

![Brutal Test: Socket Salt Spray Testing 48-Hours [Video]](/img/News/Salt Spray Test(1).jpg)

![A look inside the Great Tool Catalog [PDF Free Download]](/img/News/Why_catalog_important_cr.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.jpg)