Socket Size Basic Knowledge

How to Measure Socket Drive Size

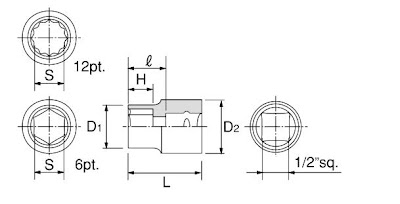

In the diagram above, the three key dimensions of a socket are labeled as Drive Hole, L, andS. These key dimensions determine the usage of this socket as follows:

Drive Hole indicates the size of the drive hole (also referred to as the "driver hole" or "square hole"), which determines the torque size of the driver tool you’ll

need. For example, you’d use a ½-inch drive socket with a ½-inch drive ratchet.

L indicates the overall socket length. The length you’ll need will be determined by your working environment. For screws in deep holes, a deep socket will be your best option.

S indicates the target size of the nut, which determines which socket you’ll need. For example, you’ll require a 5mm socket for a 5mm nut.

Drive Hole Size

The size of the Socket drive hole is determined by usage and torque demand. Common and standard socket drive sizes are as follows:1/4 inch (6.3 mm), 3/8 inch (9.5 mm), 1/2 inch (12.7 mm), 3/4 inch (19.0 mm) and 1 inch (25.4 mm).

1/4 inch (6.3 mm)

- Best Uses: Small repair jobs, such as electronics, household appliances, and small engines.

- Details: This size is ideal for small bolts and lighter torque applications. It's perfect for precision work and offers great maneuverability in tight spaces.

3/8 inch (9.5 mm)

- Best Uses: General automotive repair and home maintenance, including engine work and body components.

- Details: Known as the standard size, the 3/8-inch socket works well with mid-sized bolts. It’s a go-to for most household toolkits.

1/2 inch (12.7 mm)

- Best Uses: Medium to large equipment repair, such as trucks, SUVs, and industrial equipment.

- Details: The 1/2-inch socket handles higher torque

3/4 inch (19.0 mm)

- Best Uses: Heavy machinery and industrial equipment, like construction equipment, large trucks, and agricultural machinery.

- Details: This size is used in heavy-duty situations with larger, tougher bolts. It's a common choice for professional repair and industrial settings.

1 inch (25.4 mm)

- Best Uses: industrial equipment and machinery assembly and maintenance, such as excavators, cranes, and oil rigs.

- Details: The 1-inch socket is built for extra-large bolts and extremely high torque. It’s designed for heavy-load applications and is typically used in specialized, professional, and industrial contexts.

Learn more about Hand Tools Bolts: Selecting Guide of Hand Tool Bolts: Materials, Strength and Hex Types.

Why use inch? Because this was developed in Great Britain during the Industrial Age.

At the hardware store, you’ll find ratchet wrenches and other spanners with the above drive-hole sizes. The bigger the drive hole, the higher the torque resistance. Smaller drive holes are suitable for confined spaces. Generally speaking, 3/8 inch (9.5 mm) is the most popular size in the auto repair industry. However, it changes country by country.

Socket Sizes:SAE (INCH, fraction) & Metric (mm)

In the current market, socket sizes are divided into two systems: SAE (imperial, measured in inches) and metric (measured in millimeters). Both 6-point and 12-point sockets are measured using these two systems. The popular range is 5.5~24mm. SAE is used primarily in the United States and metric is used primarily in Europe and Asia.

Convert: 1 inch = 25.4mm

How to Convert Between SAE and Imperial Socket Sizes?

There are two different methods for measuring the hex sizes of sockets. The SAE (Society of Automotive Engineers) system uses inches, and the imperial or metric system uses millimeters.

At the hardware store, you may find yourself asking: “Why doesn’t this socket fit this nut? They appear to be very close in size!”

If you lack a clear understanding of socket sizing, it’s easy to choose the wrong tool. Without a tool of the correct size, you won’t be able to properly fix or lock the nut. Different

types of sockets are designed for specific measurement systems, so knowing the distinction between SAE and imperial sizes is crucial.How can you tell which one is the right

size?

Many customers admit that they don’t know exactly how to convert between SAE (inches) and imperial or metric (millimeters) measurements. For example, what is the actual size difference between a 11/16" hex nut and a 17mm hex nut? Will both sizes fit a 17mm

socket?

The conversion chart below shows the correlation between SAE (inches) and imperial (mm) measurements.

Tien-i: a hand tools Manufacturing Supplier has more than a decade of experience designing

and manufacturing hand tools, impact sockets and OEM items to fulfill its customers’ specific demands. If you have any special design requirements, please get

in touch with our sales team today.

The table below shows conversion from millimeters to inches and vice versa.

(Please note that these are approximate values, intended for making rough calculations)

(Click above pic to download PDF)

(Click above pic to download PDF)

Socket Length

Sockets are available in deep, semi-deep and standard sizes. You can select the length most suitable for your working environment. The semi-deep size is designed specifically for 3/8" DR.

Tien-i: a hand tools Manufacturing Supplier as the leading manufacturer ofbit sockets

andimpact sockets, Tien-I provides the full range of sockets and customized

metal processing parts.

For more information, please click below:

.jpg)

What kind of factory is Tien-i?

Is the bit head magnetic?

What is the popular size of impact sockets?

What kind of tool kit do you want? And what’s the sales territory? Different countries have different popular sizes. Welcome to send us an email for further discussion. .

linkWhat is the popular size of chrome sockets?

What kind of tool kit do you want? And what’s the sales territory? Different countries have different popular sizes. Welcome to send us an email for further discussion.

linkWhat is the difference between impact socket and chrome socket? Why is CR-V material not suitable at producing impact sockets?

Tien-i's hand sockets are made of Cr-V steel (CR-V).

Compared with the raw material "CR-V" for hand sockets, the raw material for pneumatic sockets, CR-MO, has stronger toughness, i.e. stronger shock resistance. Suitable for use with air and electric guns. CR-V steel (CR-V) has higher hardness, but in the need for shock-resistant use environment will lead to reduced service life.

to know more about hand socket and impact socketHow to get the Tien-I catalog?

How to inquiry the products which does not in the Tien-I’s catalog?

Please contact our sales team. It’s welcome to provide the relative drawing or sample and the product sales information.

Please contact our sales team. It’s welcome to provide the relative drawing or sample and the product sales information.How to get the sample? What is the sample cost?

![Brutal Test: Socket Salt Spray Testing 48-Hours [Video]](/img/News/Salt Spray Test(1).jpg)

![A look inside the Great Tool Catalog [PDF Free Download]](/img/News/Why_catalog_important_cr.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

-240px.jpg)

-240px.jpg)

(2).jpg)

.png)

.jpg)

.jpg)

![Story in Tokyo DIY Show [Site Photos]](/img/News/IMG_9495 500x500.JPG)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.jpg)