How to Design Tool Kits and Socket Sets?

Thousands of tool sets are available in hardware shops and via Amazon, and their scale and pricing range widely. You can pay ten dollars for a 32-piece set or spend thousands on a 556-piece set.

How can we design a tool set that will become a market favorite? Who is the target customer? What is the customer's industry or field of interest? What are their requirements? Before embarking upon the design process,

Tien-I’s R&D team members reflect upon the above questions, as well as the considerations set out below.

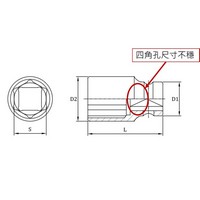

Socket drive hole size (square) related to usage

Drive hole sizes are selected according to the intended usage. Bigger drive holes have higher torque and are suitable for heavy duty application in open spaces. Smaller drive hole sizes are associated with lower torque and are mainly used for home improvement tasks and working on delicate or sensitive equipment.

The drive hole size determines the purpose of the set. The chart below shows the appropriate usage for each size range. (For a detailed explanation, please refer to our blog post on socket sizes. "Socket

Size Basic Knowledge" )

For example, a tool set containing all sizes from 1/4” to 1/2” addresses more functions, but it also bears a heftier price tag and is less convenient to transport. Also, the customer may feel that it contains too many sizes that they already have in their possession.

What is the ideal number of sockets to include in a set?

Should they be standard or deep sockets? Should one follow the SAE (inch) or metric (mm) system?

A tool set is labeled with the number of components it contains. For example, you can find a 159-piece tool kit or a 32-piece socket set. While a 32-piece socket set is sufficient for carrying out DIY home improvement tasks, this will not cover all your needs if you’re carrying out auto repair.

Conventional wisdom holds that the greater the number of components, the better. But in this case, the above is not necessarily true. The number of components may include small pieces of

less value, such as bits. You should count the

socket wrenches rather than all components. While including more sockets provides a more comprehensive range of products for the end user, this also renders the set more expensive, and less convenient to carry.

Balance is key.

Deep sockets are necessary for repairs of some special equipment and machines. They are a must-have for pro users and professional mechanics alike. When tool kits contain both deep and regular sockets, usually the deep ones prove popular, as deep hole

nuts and bolts are fairly widely used.

Metric (MM) and SAE (INCH) are the two main systems in the tool market. Usually European and Asia go for Metric (MM). England, US. and Australia use both SAE (INCH) and Metric (MM). But it still depends on the specific target market. For example, professional

auto shop may have SAE and Metric at the same time since they need to fix German car as well as US. Car. It is perfect to cover two systems, but back to the main question, how many socket/wrenches is best number?

How to Convert Between SAE and Imperial Socket Sizes?

Double Color Blow Mold Care Socket Sets - Tool Kit

133PC 1/4" & 1/2"DR. TOOL KIT (MM)

Key Features of The Ratchet Wrench

The ratchet wrench is the heart of any socket and tool set. A quality ratchet is key to user satisfaction, as it is fundamental to the socket set. When the ratchet meets ANSI or DIN specifications, the common user shouldn’t experience any problem with torque.

A key feature is the number of teeth. The greater the number of teeth a ratchet has, the smaller the angle required to move it. For example, 72 teeth = 5 degrees; 36 teeth

= 10 degrees.

For a detailed explanation, please refer to our blog post on

ratchet handle design

Additionally, three critical features of a ratchet include: (1) quick release structure; (2) trigger design; and (3) handle.

Bits, Screwdriver or Bit Socket?

Is the tool set intended for light or heavy usage? Where does the target customer use the tool and for which purpose? A screwdriver is commonly used for many DIY home improvement tasks and even for some professional tasks. The bits are suitable for occasional usage or can be combined with another accessory. If torque requirement is high, bit socket is a good choice.

Normally the tool set is designed to include the bits instead of screwdriver due to cost and utility. The screwdriver would be worthless if its tip wear out, but the bit can be replaceable. The bit socket is often used in repairing machine equipment or automobile with various length.

Philips, Pozi, slot/flat, hex/Allen key are the styles most commonly found in every workspace.

Tool case or blow molded case?

Tool kits or socket sets come in two types of cases: metal or plastic. Each market has its own preference.

Here are the general key points to consider:

- The tools or components are firmly gripped in the case, so that they resist strong impact but can still be easily taken out.

- The durability of plastic or alloy metal lock. An alloy metal clip lock is stronger and more durable than a plastic one.

- The connection between the upper and lower parts of the case varies according to whether they are made of plastic or metal. Metal makes the whole set appear sharper and more professional, and it is more durable than plastic.

- The color and design of the tool case. This is a big topic with many factors to consider. In the interest of brevity, we will show you the best example:

Tien-I's double color anti-impact design is the definition.

Tien-I is Taiwan’s trusted manufacturer of tool kits and socket sets.

Welcome to contact with Tien-I Team if you have interests with tool set or socket set design.

Being a professional hand-tool manufacturer, Tien-I produces complete

ISO and ANSI specifications for socket, impact socket, and tube spanner tools. Whether in metric or inch size, Tien-I can meet or even exceed the required specifications.Since

2004, Tien-I Company has continued todesign

and innovate the latest ergonomics hand tools in Taiwan, and ergonomics has become a part of Tien-I's design and production

DNA. If you have any inquiries, just contact Tien-I.

If you like to know more about how Tien-i design hand tool kit and socket set, simply click below button:

What kind of factory is Tien-i?

Tien-I is a manufacoturer at professional designing tool kit and producing OEM/ODM products.

Is the bit head magnetic?

Please provide the sample or the photo for us reference to see which bits you ask for.

What is the popular size of impact sockets?

What kind of tool kit do you want? And what’s the sales territory? Different countries have different popular sizes. Welcome to send us an email for further discussion. .

What is the popular size of chrome sockets?

What kind of tool kit do you want? And what’s the sales territory? Different countries have different popular sizes. Welcome to send us an email for further discussion.

What is the difference between impact socket and chrome socket? Why is CR-V material not suitable at producing impact sockets?

Tien-i's hand sockets are made of Cr-V steel (CR-V).

Compared with the raw material "CR-V" for hand sockets, the raw material for pneumatic sockets, CR-MO, has stronger toughness, i.e. stronger shock resistance. Suitable for use with air and electric guns. CR-V steel (CR-V) has higher hardness, but in the need for shock-resistant use environment will lead to reduced service life.

to know more about hand socket and impact socketHow to get the Tien-I catalog?

How to inquiry the products which does not in the Tien-I’s catalog?

Please contact our sales team. It’s welcome to provide the relative drawing or sample and the product sales information.

Please contact our sales team. It’s welcome to provide the relative drawing or sample and the product sales information.

.JPG)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

-240px.jpg)

-240px.jpg)

(2).jpg)

.png)

.jpg)

.jpg)

![Story in Tokyo DIY Show [Site Photos]](/img/News/IMG_9495 500x500.JPG)

![Brutal Test: Socket Salt Spray Testing 48-Hours [Video]](/img/News/Salt Spray Test(1).jpg)

![A look inside the Great Tool Catalog [PDF Free Download]](/img/News/Why_catalog_important_cr.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.jpg)