2-Way Wobble Extension Bar, Socket Accessory

3/8"DR. Ball End Hex Bit Socket

Impact Universal Extension Socket Set (L116)

IMPACT UNIVERSAL EXTENSION SOCKET SET (L:250)

Star Bit Socket, S2 Alloy Steel & CRV socket

Tamper Proof Star Bit Socket, Security Star Socket Bit, S2 Alloy Steel & CRV socket

Slotted Bit Socket, S2 Alloy Steel & CRV socket

Phillips Bit Socket, Phillips Screwdriver Bit Socket, S2 Alloy Steel & CRV socket

Pozidriv Bit Socket, PZ Pozi Bit Socket, S2 Alloy Steel & CRV socket

Hex HEX Bit Socket SAE/Metric, Allen Head Hex Key Socket, S2 Alloy Steel & CRV socket

Ribe BIT Socket, S2 Alloy Steel & CRV socket

XZN Triple Square Spline Bit Socket, Triple Square Bit Socket, S2 Alloy Steel & CRV socket

Universal Joint Adapter, Socket Accessory

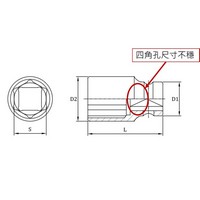

Square Drive Coupler, Square Head, Square Connector for Coupler Ratchet

Spinner Adapters, Ratchet Spinner Disks, Socket Accessory

Socket Adapter and Reducer, Square Drive Converter, Socket Accessory

Magnetic Socket Adapter and Reducer, Magnetic Square Drive Converter, Socket Accessory

Magnetic Extension Bar, Socket Accessory

Extension Bar, Socket Accessory

Wobble Extension Bar, Socket Accessory

Sliding T-Bar, Sliding T-Handle, Sliding Wrench Breaker Bar, Socket Accessory

L-Shape Extension Bar, L-Shape Handle, Socket Accessory

Speeder Handle, Speed Handle Wrench for Socket Driver, Socket Accessory

Breaker Bar, Flexible Handle, Socket accessory

3/8"DR. Hex Bit Impact Socket

1/2"DR. Hex Bit Impact Socket

3/4"DR. Hex Bit Impact Socket

1"DR. Hex Bit Impact Socket

1-1/2" DR. Hex Bit Impact Socket

1/4"DR. BALL END STAR BIT SOCKET

3/8"DR. Impact Star Bit Socket, Impact Star Bit Socket

1/2"DR. Impact Star Bit Socket, Impact Star Bit Socket

3/8"DR. Impact XZN Triple Square Spline Bit Socket

1/2"DR. Impact XZN Triple Square Spline Bit Socket

Impact Tamperproof XZN Triple Square Spline Bit Socket

1/2" Drive, Hex (Allen) Bit Impact Socket, 2-Piece Design plus Screw Bit Holder (Replaceable)

Impact Extension Bar, CR-MO Impact Grade, Laser Etched

Wobble Impact Extension Bar, CR-MO Impact Grade, Laser Etched

Magnet Impact Socket Extension, Magnetic Tips for Use with Bolts, CR-MO Impact Grade, Laser Etched

Spinning Handle Impact Extension Bar, Speed Collar, Cr-Mo Impact Grade

Adjustable Spinning Impact Extension Bar, Speed Collar, Adjustable 3-Position Aluminum Spinning Handle, Cr-Mo Impact Grade

Impact Locking Extension Bar, CR-MO Impact Grade, Laser Etched

Impact Socket Adapter and Reducer, CR-MO Impact Grade, Laser Etched, Impact Driver & Wrench Conversion

Impact Universal-Joint, CR-MO Impact Grade, Laser Etched, Flexible U-Joint Socket Accesses Hard to Reach Fasteners

Tapered Punch, Air Hammer Bits, Pneumatic Taper Punch

Tapered Punch 0.401", Pneumatic Taper Punch

.401 Shank Truck Brake Rivet Punch Air Hammer Bit 6", Air Chisel

Pneumatic Angle Scraper Air Chisel

Wide Flat Air Chisel, Bit Pneumatic Chisel 0.401 Inch Shank, Scraper Wall and Floor Scraper Tile Remover, Work with 0.401 Inch Air Hammer

Cold Air Chisel, Air Hammer Bits, Pneumatic Cold Chisel

Flat Air Chisel, .401 Air Hammer Bits, Pneumatic Cold Chisel

Special Cold Air Chisel, Angle Cold Air Hanner Bit

Cut-off & Ripping Air Chisel, .401 Shank Ripping and Cut-Off Flat Chisel, Spot Weld Splitter Chisel

Muffler Splitter Air Chisel, .401 in Shank Size, Pneumatic Splitting Tool

Splitter Air Chisel, 0.401" Shank Size, Pneumatic Splitting Tool

Tail Pipe Air Chisel, .401 shank air chisel bits, Pneumatic Control Arm Bushing Remover, Pneumatic Tailpipe Cutoff,

Spot Weld Cutter, Spot Weld Breaker, 0.401 Shank Air Hammer Bit

Spot Weld Cutter (Buster), 0.401 Shank Air Hammer Bit, Pneumatic Spot Weld Breaker

Single Blade Panel Cutter, 0.401 Shank Air Hammer Bit, Pneumatic Panel Cutter

Inside Muffler Cutter, Pneumatic ontside Muffler Cutter, 0.401 Shank Air Hammer Bit

Ball Joint Separator 11/16", Tie Rod Separator, Pickle Fork Kit, Pneumatic Separating Fork, 0.401 Shank Air Hammer Bit

Ball Joint Separator, Tie Rod Separator, Pickle Fork Kit, Pneumatic Separating Fork, 0.401 Shank Air Hammer Bit

Pneumatic Radius Cutter, Panel Cutter, 0.401 Shank Air Hammer Bit

Double Cut Body Ripper, Pneumatic Double-Cut Body Ripper, 0.401 Shank Air Hammer Bit

Double Blade Panel Cutter, Twin Blade Panel Cutter Chisel, Air Hammer Double-Bladed Panel Cutter, Pneumatic Double Cut Body Ripper, 0.401 Shank Air Hammer Bit

Deluxe Panel Cutter, Long Claw Ripper and Panel Cutter, 0.401 Shank Air Hammer Bit

Slotted Panel Cutter, 0.401 Shank Air Hammer Bit, Pneumatic Slotted Panel Cutter

Muffle And Tailpipe Remover, 0.401 Shank Air Hammer Bit, Pneumatic Muffler/Tailpipe Remover

Outside Muffler Cutter, Pneumatic Outside Muffler Cutter, 0.401 Shank Air Hammer Bit

Bushing Splitter, 0.401" Shank Size, Pneumatic Control Arm Bushing Remover, Air Hammer Bushing Splitter and Panel Cutter

Air Hammer 5/16" Nut Splitter, For Cutting 5/16" Nuts, 0.401 Shank Air Hammer Bit

Smoothing Pneumatic Air Hammer, Pneumatic Hammer, 0.401 Shank Air Hammer Bit, Glass Wood Stone for Metals

Pneumatic Tie Rod Sleeve Breaker, 0.401 Shank Air Hammer Bit

Diameter Body Smoother Hammer, Body Smoothing Hammer, Dent Repair Air Hammer 0.401 Shank

Crowfoot Wrench, Crowfoot Flare Nut Wrench, for Tight Spaces, for Automotive Repair Work

Universal T-Handle Spark Plug Socket Swivel Magnetic

T-Handle Spark Plug Socket - Tubular socket wrench for ignition core SW 20.8 mm, 160 mm long

Universal Glow Plug Socket 3/8 inch

Tire Valve Stem Puller/Installer with Tire Valve Core Tool

Telescopic Wheel Nut Wrench

BRAKE BLEEDER WRENCH 10 x 12mm - 3/8" x 5/16"

Wheel Protector Impact Socket

Adjustable T-handle Driver and Bit

Steel Automatic Center Punch with Adjustable Stroke

Serpentine Belt Installation Tool

Multi-Purpose Strap Wrench Adjustable Pipe Wrench Anti-sliding Wrench, Double Layered Thickened Nylon Strap

Valve Core Remover. Tire Valve Tool

Heavy-Duty Truck Lug Wrench - Cross Spanner

Sensor Socket, Lambda Probe Socket

1/2"DR. Torque Limiting Impact Extension Bar Set, Large Color Ring

Wide Tip Radiator Hose Pick, Hose Spoon

Notching Pliers For Electronic

3/8"DR. Drain Plug Bit (Trible Square)

3/8"DR. Drain Plug Bit (Male Triangle)

5pc Deep Combination Budd Impact Socket Set, Truck Service Impact Socket Set

3/8"DR. Drain Plug Bit (HEX)

3/8"DR. Drain Plug Bit (Female Square)

3/8"DR. Drain Plug Bit (Male Square)

Magnetic Deep Spark Plug Socket Extension, Extra Long

Straight Box Wrench (Double Socket), Tubular Socket Spanner (Box Spanner), Pipe Wrench (Socket Spanner), Heavy Duty Accurate Durable Faucet Installation Tool

Super Durable Box Wrench With Groove, Straight Box Wrench (Double Socket), Tubular Socket Spanner (Box Spanner), Pipe Wrench (Socket Spanner), Heavy Duty Accurate Durable Faucet Installation Tool

Angle Box Wrench With Groove, L Form Hex Angled Double Hex Socket Spanner, Curved Tube socket Spanner, Double-Head Elbow Hex Wrench for Mechanic Repair Tool

Tommy Bar for Pipe Socket Spanner, Rotary Mandrel, Rotary Pins

OEM & ODM Seamless Steel Pipe

5 Point Tamperproof Star Bit Socket, S2 Alloy Steel & CRV socket

5 Point Star Bit Socket, , S2 Alloy Steel & CRV socket

Locking Universal Joint, Socket Accessory

Magnetic Universal Joint, Magnetic Tips for Use with Bolts, Socket Accessory

Locking Extension Bar, Socket Accessory

Adjustable T-handle Driver and Bit, T-handle Wrench

9 Piece 1/2" Drive Tamperproof 5 Star Bit Socket Set

1/2" Drive Locking Extension Bar Set, 4 Piece,3", 5", 10", 15"

10 Piece Low-Profile Star Bit Socket Set 1/4" Drive Two Color (T10 - T50)

12 Piece Low-Profile XZN Triple Square Bit Socket Set 3/8" Drive Two Color (4 - 16mm)

9 Piece Stubby Impact XZN Triple Square Bit Socket 1/4", 3/8", 1/2" Drive Set (M4 - MT18)

10 Piece Stubby Impact Tamperproof Star Bit Socket 1/4" & 3/8" Drive Set (T10 - T50), Stubby Impact Tamperproof Star Bit Socket

Pneumatic Ball Joint Separator, Tie Rod Separator, Pickle Fork Kit, Pneumatic Separating Fork, 0.401 Shank Air Hammer Bit

Universal Extension Impact Socket

UNDERCOAT SCRAPER (1" TIP)

COMBINATION MUFFLER CUTTER

.jpg)

![Brutal Test: Socket Salt Spray Testing 48-Hours [Video]](/img/News/Salt Spray Test(1).jpg)

![A look inside the Great Tool Catalog [PDF Free Download]](/img/News/Why_catalog_important_cr.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

(1).jpg)

.jpg)

.jpg)

.jpg)

-240px.jpg)

-240px.jpg)

(2).jpg)

.jpg)

.jpg)

![Story in Tokyo DIY Show [Site Photos]](/img/News/IMG_9495 500x500.JPG)

.jpg)

.jpg)

.jpg)

.png)

.jpg)

.jpg)

.jpg)

.jpg)